| 3D打印技术在岩体物理模型力学试验研究中的应用研究与展望 |

| |

| 引用本文: | 王亚帆, 韩军, 惠乾嘉, 等. 2023. 3D打印材料模拟脆性煤岩单轴加载力学特征的初步研究[J]. 工程地质学报, 31(6): 1863-1871. doi: 10.13544/j.cnki.jeg.2021-0733. |

| |

| 作者姓名: | 王亚帆 韩军 惠乾嘉 CAO Chen |

| |

| 作者单位: | ①.辽宁工程技术大学,矿业学院,阜新 123000,中国;②.辽宁省煤炭资源安全开采与洁净利用工程研究中心,阜新 123000,中国;③.澳大利亚伍伦贡大学,新南威尔士 2522,澳大利亚 |

| |

| 基金项目: | 国家自然科学基金项目(资助号:52074145,51774174) |

| |

| 摘 要: |

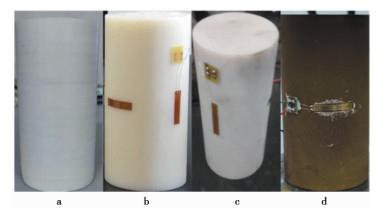

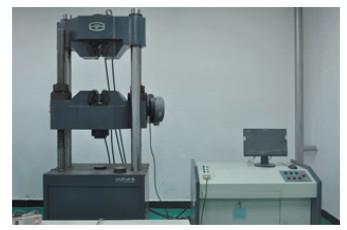

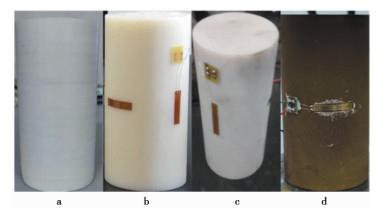

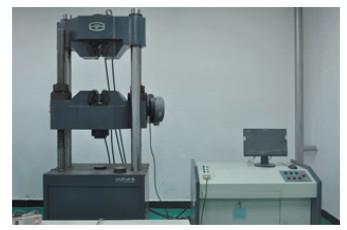

传统的岩石取样方法以及模具浇筑常受到人工操作误差及取样内部结构复杂差异大的影响,导致岩石试件获取的周期时间长,精度低,造成试样的力学试验结果离散性大。3D打印技术具有精度高、周期短、打印材料多样化等优点,考虑到岩石力学研究受到试件各向异性、结构面复杂、随机性高及试件制备存在误差等因素影响,为寻求能够模拟天然煤岩的3D打印材料,选取了聚乳酸塑料(PLA)、光敏树脂材料SLA600及Vero White Plus,以及覆膜砂粉末材料4种材料制备标准力学试验试件进行单轴压缩试验,获取了4种材料的3D打印试样的力学参数及应力-应变曲线,并对比分析了它们与煤岩的表观破裂模式的相似性。

结果表明:光敏树脂材料Vero White Plus与砂岩岩样的峰值强度、杨氏模量、泊松比及应力-应变曲线整体趋势相近;覆膜砂材料与所选煤样的峰值强度、杨氏模量及应力-应变曲线相近;表观破坏模式方面,PLA材料未发生与煤岩相似的脆性破坏;两种光敏树脂材料均发生了拉张与剪切破裂,其中SLA600材料表现出局部膨胀性,Vero White Plus材料与SLA600相比更适合模拟高强度的脆性硬岩;而覆膜砂3D打印试件的破裂特征及力学特性与低强度软岩相似,可作为低强度的脆性煤体的3D打印相似材料。

|

| 关 键 词: | 3D打印 相似材料 类煤岩试件 力学特性 |

| 收稿时间: | 2021-11-08 |

| 修稿时间: | 2021-12-11 |

|

| 点击此处可从《工程地质学报》浏览原始摘要信息 |

|

点击此处可从《工程地质学报》下载全文 |

|